Our Farming Story

The Stage of Pruning Palm Trees

The process of removing old clusters and supplying the tree with organic fertilizer and water to compensate the lost elements of the tree in the previous season and this process is carried out in mid-October

The Weeding Stage

The process of removing thorns from the new leaves of the tree to facilitate working on it.

Inoculation Stage

The stage in which the palm trees are Inoculated with the male pollen

Reduction Stage

The stage in which the number of dates grains is reduced from the clusters, so what is removed nearly two-thirds of the grain on the trees in order to get the best product in terms of size and quality.

Bending Stage

The stage in which the clusters are linked to the shape of an arch to keep the clusters from breaks-up.

Stage of Covering Dates Clusters

The stage where the clusters are placed inside the bags to protect the dates from the birds and to prevent them from falling on the ground and to facilitate the process of harvest later

Harvest Stage

The stage in which mature fruits are harvested and transported to the factory.

Stage of Receiving the Crop

At this stage, the harvested crop is received from the farm where the crop is transported in plastic boxes which are intended for transporting fruits which are arranged on clean wooden floors and then transported by closed conveyer to maintain food safety requirements, then the crops are received by the warehouse manager and quality manager, who in turn examines the fruits according to the quality standards.

Preliminary Screening Stage

At this stage, the matched crops are sorted from non-matched by trained workers, then they classify the crops as dry, damaged, wet and mild, then they remove all fruits that contain physical, insect or other damage.

Drying Stage

The crop passes this stage in the case of the existence of a mushy product resulting from the initial screening process.

Stage of Sterilization

At this stage, the crop is Sterilize with thermal sterilization equipment to be ready for next stage.

Stage of Washing and Drying Crops

At this stage, the crop is washed and cleaned from the water residue, where the crop is placed in the washing machine basin then insert the crop inside the machine to pass from the bottom of the water spray (sterilized) until it is washed, then the crop passes through the conveyor under the fans of the drying to dry it from the water residues.

Packing Stage

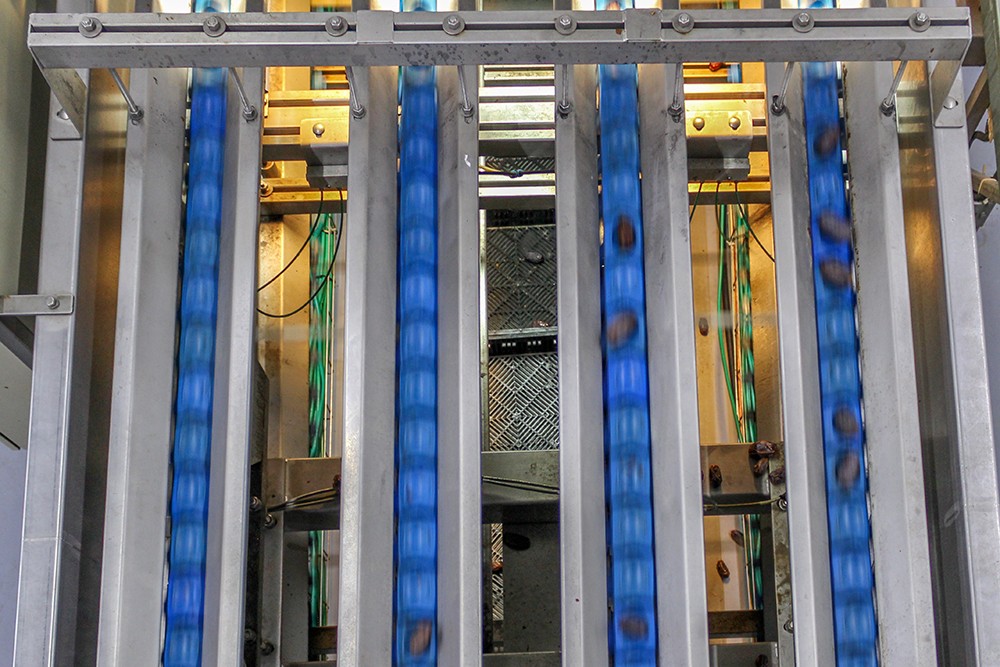

This stage is carried out in the packing house assigned to this process in order to confirm the initial screening process. The progression is done using the machine to sort the crop using special cameras, depending on size and the proportion of air in the fruit (elites)

Packaging Stage

This stage is also carried out in the packing house where the fruits are packed manually into carton containers with different sizes and weights, then the package is sealed with a plastic cover from all sides, and an outer cardboard cover and tracking number are placed on the package.

Storage Stage

At the last stage, the products are stored in the freezer at 18 °C.